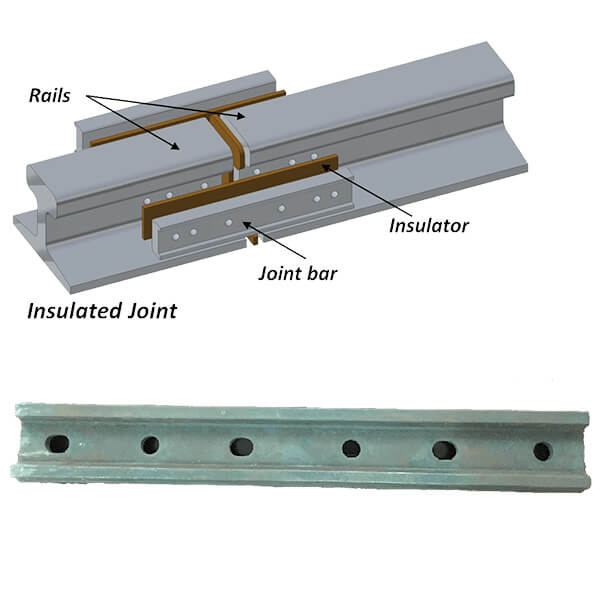

Fishplate

Types of FishPlates

| Standard | Types of Fish Plates | Material | Holes |

|---|---|---|---|

| UIC 864 | UIC54 & UIC60 | 50# & 55# | 4 holes & 6 holes |

| AREMA | 115-119RE & 132-136RE | 50# & 55# | 4 holes & 6 holes |

| ASCE | 80lb & 85lb & 90lb &100lb | 50# & 55# | 4 holes & 6 holes |

| BS 47-1 | BS75A & BS80A&BS90A&BS100A | 50# & 55# | 4 holes |

| AS 1085.2-2002 | 31kg & 41kg & 47kg | 50# & 55# | 4 holes & 6 holes |

| DIN 5902:1995 | S49 | 50# & 55# | 4 holes & 6 holes |

| TB/T 2345-2008 | P43 & P50 & P60 & P75 | 50# & 55# | 4 holes & 6 holes |

Do You Have A Railway Project We Can Help With?

GK RAILWAY

GK Group, is an enterprise manufacturing railway fasteners, whose products cover fields of railway, urban rail, mining, etc.

There are two factories located in Zhangzhou Fujian and Anyang Henan, which are all CRCC and ISO certificated, with a total area of about 320,000 ㎡, workers over 300, and an annual sales volume of over RMB 200,000,000.

Founded in 1960, With over 50 years of specializing in railway fasteners, GK has served many demanding markets worldwide, including USA States, Chile, Argentina, Ecuador, Brazil, Thailand, Indonesia, Malaysia, Vietnam, Spain, Italy, Romania, England, Kazakhstan, etc.

Our Certificates

With ISO and CRCC certificated, Guokeng tries its full efforts to save cost for each client by upgrading our Production Equipment & Inspection Facility & Quality Management System to be more efficient, economy, and also with good quality control capacity. Quality and reliability are always our culture. We will never stop upgrading and developing, and will spend our whole life in delivering best quality and service.